Unlocking the Potential of Biomass Fermentation: A Journey into Innovation and Food Safety

The Rise of the Mycoprotein 🍄

Biomass fermentation is a revolutionary process that harnesses the power of microorganisms to transform organic matter into valuable food components. This method has gained traction as a sustainable alternative to traditional agriculture, offering unique advantages in terms of resource efficiency and production versatility.

However, like any innovative technology, biomass fermentation is not without its challenges, particularly in the realm of food safety.

Understanding Biomass Fermentation

Biomass fermentation involves the use of microorganisms, such as bacteria, yeast, or fungi, to break down organic materials and convert them into useful products.

In the context of food production, this process can yield a variety of compounds, including enzymes, flavors, nutritional supplements, and other bioactive substances. By tapping into the metabolic capabilities of microorganisms, biomass fermentation enables the sustainable production of valuable food components with reduced environmental impact.

Which companies are leveraging biomass fermentation for product development?

Quorn

The origins of biomass fermentation are deeply rooted in history, with notable milestones including the launch of Quorn in 1985 by Marlow Foods, a collaborative effort between Rank Hovis McDougall (RHM) and Imperial Chemical Industries (ICI).

Commercial microbial biomass production has a multifaceted history, serving as single-cell protein (SCP) for both human and animal consumption and as viable yeast cells in the baking industry.

The industrial production of bakers' yeast traces back to the early 1900s, while yeast biomass found its way into human diets in Germany during World War I. However, the significant development of large-scale processes for the commercial production of microbial biomass as a source of protein gained momentum in the late 1960s.

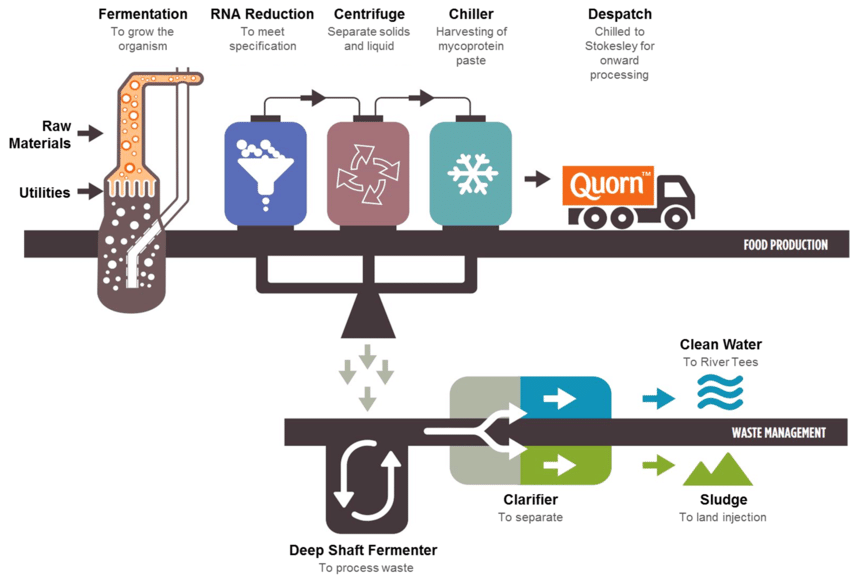

Quorn, derived from the soil mould Fusarium venenatum strain PTA-2684, undergoes a meticulous and sustainable production process to create a versatile meat substitute. Cultivated in sterile fermentation tanks with a carefully curated blend of nutrients, the fungus is nurtured to enhance its nutritional profile. After cultivation, the mycoprotein undergoes heat treatment to eliminate excess RNA, addressing past challenges related to elevated DNA or RNA levels.

The processed mycoprotein is then carefully dried, combined with egg albumen for binding, and subjected to a sophisticated texturization process, resulting in various product forms resembling meats like ground beef, chicken breasts, meatballs, turkey roasts, or diced chicken breast.

Currently, the company is under the ownership of the Philippine food conglomerate Monde Nissin, renowned for its diverse portfolio that encompasses several widely recognized ultra-processed food brands. Within this conglomerate, Quorn has expanded its offerings to include over 100 products.

Nature’s Fynd

Nature's Fynd, a startup based in Chicago and supported by prominent investors such as Jeff Bezos and Bill Gates, is at the forefront of utilising biomass fermentation for its innovative product line. The fundamental component of their offerings is a microbe discovered in the geysers of Yellowstone National Park. Rather than directly extracting from the park, Nature's Fynd opts for biomass fermentation within a factory environment.

Their proprietary Liquid-Air Interface Fermentation technology stands out, as it involves cultivating biomass on a liquid surface, a departure from the conventional submerged or solid methods.

Notably, Nature's Fynd has not merely adopted biomass fermentation but has also innovated a groundbreaking fermentation method inspired by the inherent efficiencies found in nature. This method enables the scalable growth of Fy Protein™ with a markedly lower environmental impact compared to traditional protein sources.

The company has successfully launched two product lines: Meatless Breakfast Patties and Dairy-Free Cream Cheese (Original/Onion & Chives), with a third product expected to debut in early 2024.

Some examples of other companies leveraging biomass fermentation methods for the development of food products/ingredients include Calysta, Aqua Cultured Foods, Adamo Foods, Millow, and Cultivated Biosciences.

What are the key food safety concerns in biomass fermentation?

Microbial Contamination: Microbial control is a paramount concern in biomass fermentation. The process relies on carefully selected microorganisms to carry out specific transformations. Unwanted contaminants can compromise the quality and safety of the final product. Strict monitoring and control measures are essential to prevent the introduction of harmful microorganisms.

Allergen Management: Biomass fermentation may involve the use of allergenic substrates or the generation of products with allergenic properties. Ensuring effective allergen management throughout the entire fermentation process is critical to prevent allergic reactions in consumers. Rigorous testing and labeling practices are crucial to communicating potential allergen risks accurately.

Residue and By-Product Control: Depending on the biomass used, the fermentation process might introduce residues or by-products that could pose safety concerns. Comprehensive analysis and purification techniques are required to minimize the presence of undesirable compounds and ensure the purity of the final product.

Consistency in Product Quality: Maintaining consistency in product quality is a challenge in biomass fermentation. Variations in fermentation conditions, such as temperature, pH, and nutrient availability, can impact the yield and composition of the final product. Strict process control and optimization are necessary to ensure a consistent and safe end product.

Regulatory Compliance: As biomass fermentation gains prominence, regulatory bodies are developing guidelines to ensure the safety of products derived from this method. Food producers must stay abreast of evolving regulations and comply with established safety standards to navigate the dynamic regulatory landscape successfully.

What is SFA doing to reduce food safety risks for these fermentation-generated ‘Future Foods’?

Novel Foods resulting from fermentation are categorized as such and necessitate approval from the Singapore Food Agency (SFA) before being permitted for sale.

Manufacturers planning to market these foods must undertake safety assessments of their products, which will undergo SFA scrutiny.

The evaluation by SFA involves a thorough examination of the manufacturing processes, including inputs and safety testing performed on the food product, to ascertain its safety for consumption.

Key considerations in this assessment encompass, but are not confined to:

Determining the safety of the microorganism and assessing its potential to produce allergens or other harmful substances.

Identifying possible avenues for the entry of chemical and microbiological contaminants into the manufacturing process and ensuring that the manufacturer has addressed these concerns.

Verifying whether the product has undergone comprehensive food safety testing to ensure that contaminant levels fall within established safe limits.

Similar to all other foods, novel foods resulting from fermentation, once approved, are subject to ongoing market monitoring.

This ensures that manufacturers consistently adhere to stringent safety standards in the production of such foods, maintaining a commitment to high levels of safety for consumers.

For more information about SFA’s regulatory framework for novel foods, please visit: https://www.sfa.gov.sg/food-information/novel-food